METALogic - TÜV AUSTRIA Group

Contact:

Erik Thomas

Phone: +32 16 39 60 00

E-Mail: Erik.Thomas@METALogic.be

Contact:

Erik Thomas

Phone: +32 16 39 60 00

E-Mail: Erik.Thomas@METALogic.be

KEYWORDS:

- science and technology

- water

- electricity production and distribution

- oil and gas - downstream activities

- gas

- fuel

- materials

- corrosion

- hydrogen

attachments to announcement

Corrosion know-how facilitates the use of hydrogen as the fuel of tomorrow

back to announcementphotos

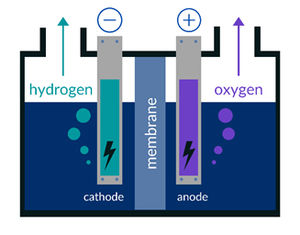

[ download press photo ] | title: Electrolyzer, a plausible solution? image text: As illustrated in the figure above, electricity causes water to evaporate into either hydrogen (via cathode) or into oxygen (via anode). The cathode and anode are held into place by a metal plate with a porous layer and coated with a catalyst which kickstarts the reaction. Between the plates are membranes for the transport of ions and water between the different sections. copyright: METALogic - TÜV AUSTRIA Group |

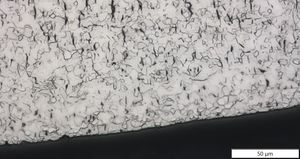

[ download press photo ] | title: Corrosion facilitates use of hydrogen image text: Hydrogen gas has different properties than natural gas. The pipes are specifically created to transport natural gas and since they are susceptible to failure mechanisms specific for hydrogen, this causes the pipes to not be as suitable to transport hydrogen. Hydrogen can cause embrittlement of the material and results in a higher risk of accidental release of hydrogen gas through fracture. copyright: METALogic - TÜV AUSTRIA Group |

[ download press photo ] | title: Electrolyzer, a plausible solution? image text: Although titanium has beneficial properties for use as base material in fuel cells, hydrogen does react with titanium. This reaction results in the formation of titanium hydride (TiH2) which causes the base material to be more brittle. When titanium is chosen in fuel cells, extra measures are taken against hydrogen embrittlement by applying surface coatings like titanium nitride. copyright: METALogic - TÜV AUSTRIA Group |