Contact:

Monika Hutter / Manager Corporate Communications & Marketing

Phone: +43 5 9888-11322

E-Mail: monika.hutter@cargo-partner.com

| Pressbox |

|

| The new generation of turbo prop |

| [ photos ] |

Vienna (pts021/13.06.2007/11:30) - Some radical changes have to be made and they have to be made before politics and economical circumstances lead into even more dramatic and not any more controllable changes. The change of climate is a fact that nobody can deny and we must therefore take responsible actions.

Actions to save the climate will in the long run prove also economically very beneficial for the airline industry which can not carry on with the present exhaustion of CO2 and other greenhouse gases without consequences - and this in a market growing every year at a rate of 5 % or more.

Consequences

There are several sorts of consequences that can be expected. The worst of it will be that not only the oil price will increase tremendously. It is possible that by 2027 oil will simply not be available in the requested quantities for purposes like air transportation and all the aircrafts designed today will technically still be in service until 2030 or 2040. But economically or politically, employment will not be possible any more and no serious investor can neglect such considerations. We have believed too long that the amount of air in our atmosphere is unlimited and now are proven wrong. Is it a sacrilege to realize that also the amount of exploitable crude oil on our planet is limited and the question will have to be put sooner or later to what purpose it can be used.

Truly nobody can know in 2007 what 2027 will have brought, but it is a likely scenario investors have to deal with and every airline is a big investor. So the first ones are making their conclusions already, like Richard Branson of Virgin Airlines, who is heavily investing on alternatives to fossil oil. Virgin is quite advanced in its attempts to add renewable liquid fuels to kerosene together with Boeing and Pratt & Whitney engines, and only recently an aircraft with a 50: 50 ethanol-kerosene mix has crossed the Atlantic.

Fine-tuning or radical innovation

Richard Branson has set another act of unconventional thinking and experience has taught us that this is probably an advantage for his Virgin group. It has been realized and more importantly put into action that further fine-tuning of existing systems cannot be the solution. There must be radical changes and in this case it means to stop burning fossil oil. The replacement of kerosene by renewable forms of energy is very good, but in quantity limited as long as it is dependent on the availability of farmland and in later years hopefully of woods. The other way is to employ more economical airplanes and modes of propulsion than the usual turbofan jet engines. Therefore we are strongly interested in the development of a new generation of High Speed Turbo Props (HSTP), like the A 400 M, which goes at 0.68 to 0.72 Mach and needs according to Airbus Industries 20 % less fuel than if it was propelled by the best turbofan engines.

20 % economy on fuel is a lot, but will it be enough to salvage the Earth climate?

This is already a fair contribution and further technical improvements on this new system will be made. I have a clear idea about it. Similar to what we have experienced in the car industry there will be an increase of fuel efficiency through more powerful turbo-loaders and this will be made possible through a completely new configuration of the turbo prop only.

The new generation of turbo prop

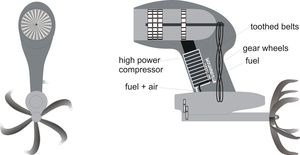

The propeller blades will have a different configuration, with the tips pointing far back, and there will be a solution for the turbulences when the propeller tips come near sonar speed. Ways will be found to reduce them and to even utilize the rest of them for reducing other turbulences. The compressor will be much bigger and separated from the prop, the fuel/air mixture will be prepared in a separate high-pressure chamber and then injected into the gas turbine.

The propeller will be behind the engine and pushing instead of pulling, like it was realized in the past from time to time. The pushing propeller uses the slower and thicker air under the wing. I expect the additional fuel economy of such a HSTP to be at least 15 % in advance compared with the engines of the A 400 M and the engines being considerably more powerful than these already employed ones. Furthermore it will be possible to better use other fuels like bio-ethanol through the pre-preparation of the fuel/air mix.

Where my ideas come from and what makes me sure

Many or most of the real innovations have started with a clear vision and that is just what I happen to have about this HSTP. I am sure that some people in the construction departments of the big aircraft producers know about all my considerations. The new aspect about I want to draw the attention to is that the expected economical environment for their product will change dramatically. In view to the long life cycles a corresponding fundamental innovation is needed - which can be offered through the HSTP. Fuel economy and CO2 exhaustion are the decisive factors for an aircraft's profitability in future. We know already today that there will be a considerable increase in oil prices, fuel taxation, proportional airport charges based on fuel consumption, customer's climate awareness and there is more to come.

I encourage the aviation industry to go into competition to Realizing this HSTP first would be of tremendous advantage to the world's climate and if this alone is not enough motivation, for the whole airline and aviation industry.

Statement of Stefan Krauter, CEO and owner of the cargo-partner group that is present in 14 European countries and has a total of 50 offices and subsidiaries. The company has a total of 1,150 employees in Europe. In 2006, consolidated sales reached about 245 million euro.

(end)

|

|